CV PSE Certified PV Wire 600V

CV PSE Certified PV Wire 600V Application

These CV cables have superior environmental performance in terms of weather, heat and cold resistance, and are best suited for cabling in solar power generation systems. This cable is sunlight, ozone, UV, and moisture resistant. Photovoltaic Wire (PV Wire) may be used as wiring for solar panels, as the interconnection wiring of grounded and ungrounded photovoltaic power systems.

Characteristic:

Electron-beam cross-linked compounds; UV, ozone and hydrolysis resistant; High temperature resistant, the materials do not melt or flow; Good cold flexibility; Very long expected service life span of more than 25 years at 90℃; Excellent weather-resistant, cold-resistant, flexible, heat-resistant and oil-proof properties Compatible to all popular connectors, PSE Certified

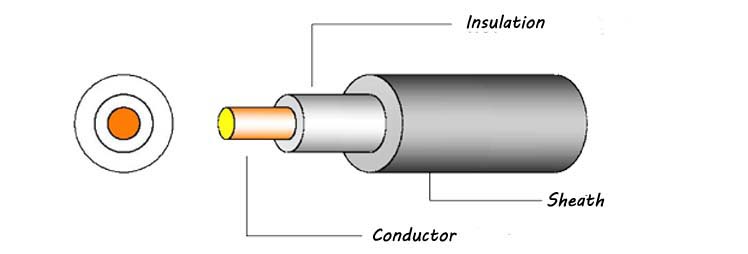

CV PSE Certified PV Wire 600V Construction

| Conductor material: | Stranded bare copper or tinned copper, electrical Property & Structure in accordance with JIS C 3102 and JIS C 3152 flexible conductor |

| Insulation: | LSZH electron-beam cross-linked Polyolefin copolymer, ROHS material |

| Sheath: | Lead-free PVC, Sheath color: Black, White |

CV PSE Certified PV Wire 600V Technical Data

| Rated Voltage U | 600V |

| Test Voltage U | No breakdown at 1.5KA (AC), 50Hz, 5min, 20 ±5 ℃ |

| Bending Radius | Fixed installation>4D; Occasionally moved>5D |

| Rated Temperature | +90℃ |

| Mineral Oil Immersion | JIS C 3605 |

| Impact at low temperature | JIS C 3605 |

| Flame retardance: | The flame shall go out spontaneously within 60s |

| Smoke density | JIS C3605 |

CV PSE Certified PV Wire 600V Specification

| Cross Section (mm2) |

Conductor

Constuction |

Conductor

Stranded OD.(mm) |

Cable OD.(mm) | Conductor Max.

Resistance @20℃ (Ω/km) |

Insulation

Resistance MΩ.km |

Test Voltage (VAC) |

| 2.0 | 7/0.60 | 1.80 | 6.4 | 9.24 | 2500 | 1500 |

| 3.5 | 7/0.80 | 2.40 | 7.0 | 5.20 | 2500 | 1500 |

| 5.5 | 7/1.00 | 3.00 | 8.0 | 3.33 | 2500 | 1500 |

| 8.0 | 7/1.20 | 3.60 | 8.6 | 2.31 | 2000 | 1500 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.