TPYC High Voltage Shipboard Power Armored Cable

TPYC High Voltage Shipboard Power Armored Cable Application

TPYC High Voltage Shipboard Power Armored Cable is intended for shipboard and off-shore building to transmit power.

TPYC High Voltage Shipboard Power Armored Cable Standards:

Design guide:

JIS C 3410(2010),

IEC 60092-350(2008-02),

IEC 60092-351(2004-04)

IEC 60092-353(2001-04),

IEC 60092-354(2003-06),

IEC 60092-359(1999-08)

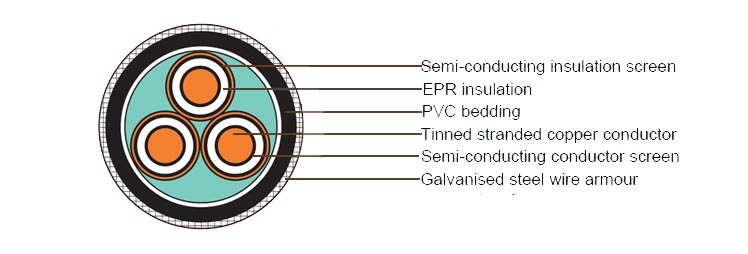

TPYC High Voltage Shipboard Power Armored Cable Model&Construction

3.6/6KV, 6/10KV, 8.7/15KV

(FA-)SPYC, SPYCB, TPYC

| Conductor | T(S) | Tinned annealed stranded copper, class 2 according to IEC 60228 |

| Conductor screen | Semi-conducting compound | |

| Insulation | P | 85°C EPR as per IEC 60092-351 |

| Insulation screen | Semi-conducting compound /Tinned copper tape | |

| Filler | Non-hygroscopic material (If necessary) | |

| Bedding | Y | PVC, ST2 type |

| Armor | C (CB) |

Galvanized steel wire braid(-C TYPE) or copper alloy wire braid(-CB TYPE) |

| Core identification | 3C Red, Yellow, Blue | |

| Outer sheath color | Red |

High Voltage Shipboard Power Armored Cable Specification

3.6/6KV (FA-) SPYC, SPYCB

| Conductor | Insulation Thickness |

Bedding thickness |

(FA-) SPYC, SPYCB | ||||

| Size | Construction | O.D | Nominal overall Dia. |

Tolerance | Cable weight (Approx.) |

||

| mm² | No./mm | mm | mm | mm | mm | mm | Kg / Km |

| 10 | 7/1.35 | 4.05 | 2.5 | 1.3 | 17.4 | 0.9 | 480 |

| 16 | 7/1.7 | 5.1 | 2.5 | 1.4 | 18.7 | 0.9 | 680 |

| 25 | 7/2.14 | 6.42 | 2.5 | 1.4 | 20 | 1 | 830 |

| 35 | 7/2.52 | 7.56 | 2.5 | 1.5 | 21.3 | 1.1 | 970 |

| 50 | 19/1.78 | 8.9 | 2.5 | 1.5 | 22.7 | 1.1 | 1160 |

| 70 | 19/2.14 | 10.7 | 2.5 | 1.6 | 24.7 | 1.2 | 1370 |

| 95 | 19/2.52 | 12.6 | 2.5 | 1.7 | 26.8 | 1.3 | 1740 |

| 120 | 37/2.03 | 14.2 | 2.5 | 1.7 | 28.4 | 1.4 | 2010 |

| 150 | 37/2.25 | 15.8 | 2.5 | 1.8 | 30.2 | 1.5 | 2450 |

| 185 | 37/2.52 | 17.6 | 2.5 | 1.9 | 32.8 | 1.6 | 2650 |

| 240 | 61/2.25 | 20.3 | 2.6 | 2 | 35.8 | 1.8 | 3200 |

| 300 | 61/2.52 | 22.7 | 2.8 | 2.1 | 38.9 | 1.9 | 4150 |

3.6/6KV (FA-) TPYC

| Conductor | Insulation

Thickness |

Bedding

thickness |

(FA-) TPYC | ||||

| Size | Construction | O.D | Nominal overall

Dia. |

Tolerance | Cable weight

(Approx.) |

||

| mm² | No./mm | mm | mm | mm | mm | mm | Kg / Km |

| 10 | 7/1.35 | 4.05 | 2.5 | 1.9 | 34.5 | 1.7 | 1180 |

| 16 | 7/1.7 | 5.1 | 2.5 | 2 | 36.9 | 1.8 | 1680 |

| 25 | 7/2.14 | 6.42 | 2.5 | 2.1 | 40 | 2 | 2130 |

| 35 | 7/2.52 | 7.56 | 2.5 | 2.2 | 42.7 | 2.1 | 2550 |

| 50 | 19/1.78 | 8.9 | 2.5 | 2.3 | 45.8 | 2.3 | 3130 |

| 70 | 19/2.14 | 10.7 | 2.5 | 2.5 | 50 | 2.5 | 3750 |

| 95 | 19/2.52 | 12.6 | 2.5 | 2.7 | 54.4 | 2.7 | 4880 |

| 120 | 37/2.03 | 14.21 | 2.5 | 2.8 | 58.2 | 2.9 | 5690 |

| 150 | 37/2.25 | 15.75 | 2.5 | 2.9 | 61.8 | 3.1 | 7100 |

| 185 | 37/2.52 | 17.64 | 2.5 | 3.1 | 66.2 | 3.3 | 8600 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.