GGDUR High Flexible Energy Chain Motor Cable

GGDUR High Flexible Energy Chain Motor Cable Application

GGDUR High Flexible Energy Chain Motor Cable is suitable for dry or wet rooms and installation without strong stress or free continuous reciprocated movement. This motor cable is intended for working places like woodworking machines, machine tool equipment, logistics conveyor systems, crane, and other similar equipment. This cable is especially suitable for heavy machinery, coastal, port, field, high and low temperature, high pollution, and other harsh environment places.

This energy chain motor cable is specially designed for applications that need repeatedly bend and movement. The cable is cheap and can be widely used in the towline system, robot, processing equipment, production line, warehouse, cranes, port equipment, and so on.

Because of its special PUR sheath, This cable is flame retardant, abrasion resistant, ozone, and UV resistant, oil resistant.

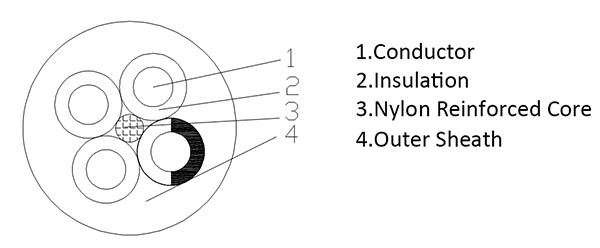

GGDUR High Flexible Energy Chain Motor Cable Construction

| Conductor | Finely stranded bare copper wire,VDE0295 Class 6 |

| Insulation | PVC Special Compound |

| Reinforcement element | Nylon wire |

| Sheath | PUR Compound,Black(RAL9005) |

Code Design

| Cable for Port machinery | G |

| Reinforced | G |

| For Motor systems | D |

| PUR Sheath | U |

| Flexible Conductors | R |

GGDUR High Flexible Energy Chain Motor Cable Technical Data

| Rated Voltage | 600/1000V |

| Conductor long term working temperature | 100℃ |

| Min.Working temperature | -35℃ |

| Test Voltage | 3.5kV/5min |

| Min.Bending radius | 6OD |

GGDUR High Flexible Energy Chain Motor Cable Specification

| Cross section(mm2) | Conductor construction ( tinned copper) | Nom. OD of Cable(mm) | Max. OD of Cable(mm) | Approx weight(kg/km) |

| 1×4 | 1×126/0.20 | 6.7 | 7.4 | 79 |

| 1×6 | 1×189/0.20 | 7.6 | 8.3 | 105 |

| 1×10 | 1×322/0.20 | 8.9 | 9.8 | 155 |

| 1×16 | 1×513/0.20 | 10.3 | 11.3 | 222 |

| 1×25 | 1×798/0.20 | 12.1 | 13.3 | 328 |

| 1×35 | 1×1121/0.20 | 13.5 | 14.9 | 435 |

| 1×50 | 1×703/0.30 | 15.7 | 17.3 | 599 |

| 1×70 | 1×999/0.30 | 18.4 | 19.9 | 836 |

| 1×95 | 1×1332/0.30 | 20.2 | 21.8 | 1075 |

| 1×120 | 1×1702/0.30 | 22.0 | 23.8 | 1341 |

| 1×150 | 1×2109/0.30 | 24.4 | 26.4 | 1653 |

| 1×185 | 1×1443/0.40 | 27.0 | 29.2 | 2004 |

| 4×1.5 | 4×48/0.20 | 11.3 | 12.2 | 157 |

| 4×2.5 | 4×77/0.20 | 12.5 | 13.7 | 206 |

| 4×4 | 4×126/0.20 | 13.9 | 15.3 | 286 |

| 4×6 | 4×189/0.20 | 16.4 | 18.1 | 391 |

| 4×10 | 4×322/0.20 | 20.1 | 21.7 | 610 |

| 4×16 | 4×513/0.20 | 23.2 | 25.0 | 852 |

| 4×25 | 4×798/0.20 | 27.5 | 29.7 | 1279 |

| 4×35 | 4×1121/0.20 | 32.5 | 34.5 | 2050 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.